Jigs and Fixtures: More Profitable Production

Deliver real value to manufacturers with 3D printing. Tooling has always been one of the most expensive and time-consuming processes in the production cycle, not anymore.

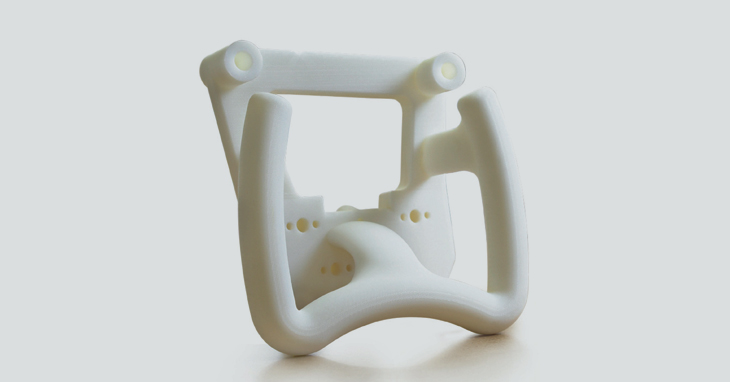

Bell Helicopter’s Xworx prototyping lab used FDM to build functional models of communication-wiring conduit for the Osprey

Real Challenge

Bell Helicopter manufactures the heavy-lift “tiltrotor” Osprey, the hybrid aircraft that combines features of both airplane and helicopter to accomplish what none of its forbears can do. It can lift off, hover, and land vertically yet it can cruise at high altitudes at jet speeds.

Real Solution

When the aircraft recently underwent an experimental tail-wiring upgrade, technicians at the rapid prototyping lab at Bell Xworx used a Fortus FDM (fused deposition modeling) system to build tough polycarbonate wiring conduits. Technicians installed the branching conduits in six mating sections inside the Osprey’s twin vertical stabilizers for on-the-ground testing of its wiring.

PLease Kindly provide the details of your enquiry below

and we will endeavor to get back to you as soon as possible

White Paper

White Paper

Deliver real value to manufacturers with 3D printing. Tooling has always been one of the most expensive and time-consuming processes in the production cycle, not anymore.

White Paper

White Paper

3D printing is becoming a part of the game plan for those is the aerospace industry. Learn more how is stacks up against traditional manufacturing in our whitepaper

Case Study

Case Study

From the start, the Boom team knew 3D printing was going to play a crucial role in the development of XB-1, and ultimately for Overture. Download whitepaper to know more.